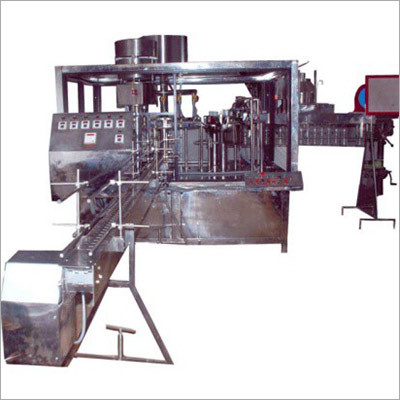

Carbonator Tank with Pump and Motor Assembly

Carbonator Tank with Pump and Motor Assembly Specification

- Warranty

- 1 Year

- Frequency

- 50 Hertz (HZ)

- Usage & Applications

- Industrial

- Material

- Mild Steel

- Voltage

- 220-440 Volt (v)

- Product Type

- Carbonator Tank with Pump and Motor Assembly

- Drive Type

- Electric

Carbonator Tank with Pump and Motor Assembly Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 7 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Carbonator Tank with Pump and Motor Assembly

A component frequently used in beverage manufacturing and dispensing systems is a carbonator tank with pump and motor assembly, especially for carbonated beverages like soda, sparkling water, and beer. The assembly is in charge of adding carbon dioxide (CO2) to the beverage in order to give it the desired effervescence.

The major parts of a carbonator tank with pump and motor assembly are broken down below along with what they accomplish in the following order:

1. The carbonator tank is a pressurised container that houses the beverage that has to be carbonated. Typically constructed of stainless steel, it is intended to endure the pressure brought on by carbonation.

2. Pump: The beverage is transferred from the tank and forced through the carbonation process with the help of the pump. In order to facilitate the solubility of carbon dioxide into the liquid, it generates the necessary pressure. Depending on the particular needs of the application, positive displacement pumps or centrifugal pumps are frequently employed in carbonation systems.

3. The motor assembly, which is necessary for the pumps operation, is made up of an electric motor and other related parts. The pump is driven mechanically by the motor, allowing the beverage to flow through the carbonator assembly.

4. As the beverage moves through the carbonator tank, a device called a carbon dioxide injector (CO2) injects CO2 into the mixture. It typically consists of a nozzle or diffuser that spreads the CO2 into tiny bubbles, increasing the area where the gas and liquid come into contact to carbonate the beverage.

5. Pressure Regulator: To regulate and maintain the desired pressure inside the carbonator tank, a pressure regulator is frequently incorporated into the assembly. By controlling the flow of CO2 into the tank and avoiding over-pressurization, it provides constant carbonation levels.

6. Valves and Piping: To regulate the flow of the beverage and CO2 during the carbonation process, the assembly contains a variety of valves and piping. These parts aid in guiding the liquid and gas to the intended areas inside the assembly, enabling effective system operation and carbonation.

A bigger beverage manufacturing or distribution system is often connected with the carbonator tank, pump, and motor assembly. A complete carbonation system can be made by connecting it to additional parts such mixing tanks, filters, chillers, and beverage dispensers.

Its vital to remember that a carbonator tank with pump and motor assemblys design and specs might change depending on the application, output, and desired carbonation levels. To preserve the longevity and performance of the assembly and to maintain the desired levels of carbonation in the beverages produced, proper maintenance, regular cleaning, and adherence to safety regulations are crucial.

Efficient Industrial Carbonation Solution

Designed for industrial use, this Carbonator Tank with Pump and Motor Assembly provides a seamless and controlled carbonation process. Its electric drive ensures consistent delivery of results, while the sturdy mild steel construction guarantees durability in demanding working environments. A comprehensive one-year warranty adds reliability, making this system a preferred choice for manufacturers and processing facilities seeking dependable carbonation equipment.

Versatile Design and Power Compatibility

This assembly is built for versatility, supporting a wide voltage range of 220-440 volts and a standard frequency of 50 Hz, which makes it compatible with various industrial electric systems. Supplied by a reputable exporter and manufacturer in India, the product is tailored to meet diverse operational requirements across multiple industries where carbonation processes are essential.

FAQs of Carbonator Tank with Pump and Motor Assembly:

Q: How is the Carbonator Tank with Pump and Motor Assembly installed in industrial settings?

A: The assembly is designed to be easily integrated into industrial setups by connecting it to your existing pipelines and power supply (220-440V, 50Hz). Detailed installation manuals and technical support are provided by the manufacturer to ensure a smooth setup process.Q: What materials are used in manufacturing this carbonator tank, and how does this benefit industrial use?

A: The tank and assembly are constructed from mild steel, offering high durability and corrosion resistance. This material choice ensures a long lifespan and low maintenance requirements, which is particularly beneficial for continuous industrial operation.Q: When can I expect delivery and technical support for this product?

A: As an Indian exporter and manufacturer, products are shipped promptly upon order confirmation. Technical support is available right from installation and during the operation phase throughout the one-year warranty period to ensure uninterrupted usage.Q: Where is the Carbonator Tank with Pump and Motor Assembly manufactured, and can it be exported internationally?

A: The product is manufactured in India by experienced industrial equipment producers. It is available for both domestic supply and international export, making it accessible to industries worldwide.Q: What is the process for claiming the one-year warranty if an issue occurs?

A: If any defects or issues arise within the warranty period, you can contact the supplier or manufacturer with the purchase details. They will arrange for repair or replacement as per the warranty terms, ensuring minimal downtime for your operations.Q: What are the main industrial applications for this carbonator tank assembly?

A: This equipment is primarily used in industries requiring controlled carbon dioxide infusion, such as beverage manufacturing, chemical processing, and water treatment facilities. Its robust build and reliable motor-pump assembly make it suitable for continuous, large-scale operations.

More Products in Soda Soft Drink Plant Category

Aeriated Water Filler and Cork Sealer

Minimum Order Quantity : 1 Piece

Frequency : 50 Hertz (HZ)

Usage & Applications : Industrial

Water Source : River Water

Material : Mild Steel

Warranty : 1 Year

Glass Bottle Washing Unit

Minimum Order Quantity : 1 Piece

Frequency : 50 Hertz (HZ)

Usage & Applications : Industrial

Water Source : River Water

Material : Mild Steel

Warranty : 1 Year

|

|

|

|

ACCURAL BIOTECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry