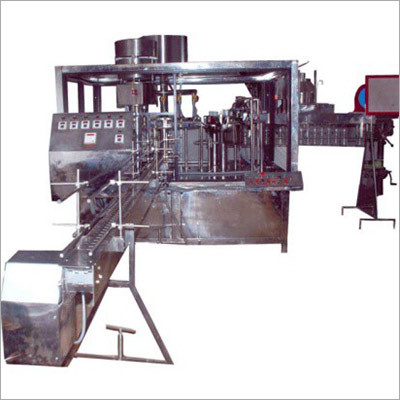

Fully Auto Heat Shrink Labeling Machine

Fully Auto Heat Shrink Labeling Machine Specification

- Usage

- Industrial

- Power Supply

- Electric

- Material

- Mild Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Voltage

- 220 Volt (v)

- Warranty

- 1 Year

Fully Auto Heat Shrink Labeling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Fully Auto Heat Shrink Labeling Machine

A specialised tool used to apply heat shrinkable labels to various containers or items is a fully automatic heat shrink labelling machine. The machine automates the labelling procedure and uses heat to ensure precise label placement and strong adhesion.

The main parts and procedures of a typical fully automatic heat shrink labelling machine are described in the following overview:

1. The machine is outfitted with a label supply system, which may comprise a magazine or a roll holder for labels. The heat shrink labels are frequently supplied in roll form and are pre-printed. Labels are fed into the labelling mechanism from a label roll that has been loaded onto the machine.

2. Container feeding: Through a conveyor system or an automated container feeding mechanism, containers like bottles, jars, or cans are fed into the machine. In preparation for labelling, the containers move along the conveyor belt or are held in position by a container holder.

3. Labelling Mechanism: A number of parts work together to apply heat shrink labels to the containers using the labelling mechanism. Depending on the particular machine model, the precise design and operation may vary, but commonly includes the following:

- The labels are dispensed from the label roll and directed towards the labelling point during label dispensing. A labelling head may be used to separate and place the labels for application.

- Labelling Mechanism: The heat shrink labels are precisely applied to the containers using the labelling mechanism. Before the labels are shrunk, they are placed and lined up with the containers.

- Labelled containers pass through a heat shrink tunnel after being labelled, causing the labels to shrink. Heat sources like hot air or steam are installed in the tunnel to heat the labels, causing them to shrink and closely adhere to the curvature of the container.

- Cooling system: Following label shrinkage, the containers may be cooled to firm the labels in their new location.

4. Container Handling: The containers move along the conveyor or through a container handling system to the next step of the manufacturing process once the labels have been shrunk and chilled. Additional processing, packing, or inspection may be part of this.

5. Control system: The labelling procedure is supervised by the machines control system, which also regulates container handling, heat shrink tunnel temperature, label placement, and label dispensing. Specific labelling parameters can be entered into the control system and changed as necessary.

6. Quality Control: To ensure label accuracy, label alignment, and label adhesion, some fully automatic heat shrink labelling equipment may have quality control capabilities. In order to verify that the labelled containers match quality standards, this may utilise sensors or cameras.

Depending on the machine model, the kind of containers being labelled, and the production needs, a fully automatic heat shrink labelling machines features and operation may differ. Additional features like programmable labelling parameters, real-time monitoring, and data logging capabilities may be incorporated with more advanced devices.

To ensure the effective and dependable operation of a fully automatic heat shrink labelling machine as well as to preserve the quality and accuracy of the labelled containers, regular maintenance, cleaning of machine components, and adherence to safety regulations are essential.

Efficient Labeling for Industrial Applications

This heat shrink labeling machine excels in delivering consistent and high-quality results for large-scale industrial usage. It simplifies the labeling process, reducing manual effort and increasing throughput. Its design allows for seamless integration into various production lines, ensuring flexibility across different manufacturing environments.

User-Friendly Semi-Automatic Operation

Featuring an intuitive Human Machine Interface control system, this semi-automatic machine enables easy operation and monitoring. The absence of computerization means reduced complexity and straightforward maintenance, making it suitable for operators of all skill levels.

FAQs of Fully Auto Heat Shrink Labeling Machine:

Q: How does the Fully Auto Heat Shrink Labeling Machine operate?

A: The machine uses electric power to apply heat shrink labels to products. Operators interact with the Human Machine Interface to set parameters and oversee the labeling process, ensuring accuracy and efficiency.Q: What types of labels or containers can this machine handle?

A: The heat shrink labeling machine is suitable for a wide range of containers used in industrial settings. It can be adapted to label bottles, jars, and other compatible products based on your production requirements.Q: When is it necessary to use a heat shrink labeling machine in manufacturing?

A: A heat shrink labeling machine is essential when you require secure, tamper-evident labeling and a professional finish on your products. Its especially beneficial in industries that demand high-volume production and consistent labeling standards.Q: Where is this machine manufactured and supplied from?

A: This machine is manufactured, exported, and supplied in India, reaching various markets for industrial labeling needs both domestically and internationally.Q: What benefits does the semi-automatic feature offer?

A: The semi-automatic function combines efficiency with user control, reducing manual intervention while allowing operators to customize label placement. Its ideal for circular production lines or diverse container sizes.Q: How is the warranty and support structured for this labeling machine?

A: Customers receive a one-year warranty, ensuring peace of mind and reliability. Service and support are readily available through the manufacturers network in India.

More Products in Pet Bottle Labeling Machine Category

Fully Auto Glue Labeling Machine

Minimum Order Quantity : 1 Piece

Computerized : No

Control System : Human Machine Interface

Material : Mild Steel

Automatic Grade : SemiAutomatic

Power Supply : Electric

|

|

|

|

ACCURAL BIOTECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry