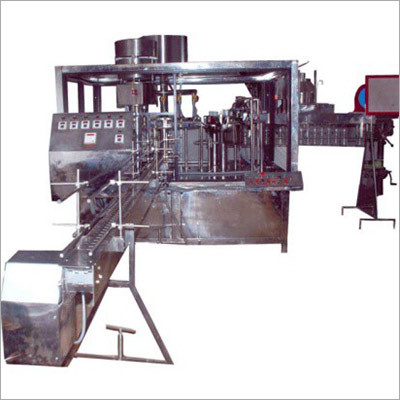

Fully Auto Glue Labeling Machine

Fully Auto Glue Labeling Machine Specification

- Usage

- Industrial

- Power Supply

- Electric

- Material

- Mild Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Voltage

- 220 Volt (v)

Fully Auto Glue Labeling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Fully Auto Glue Labeling Machine

A specialised tool used to apply adhesive labels to various containers or items is a completely automatic glue labelling machine, sometimes referred to as an automatic adhesive labelling machine. The device is made to automate labelling, offering quick and precise labelling for productive production lines.

An overview of the main elements and procedures in a typical fully automatic glue labelling machine is provided below:

1. The machine is outfitted with a label supply system, which may comprise a magazine or a roll holder for labels. The labels are normally provided in roll form and are pre-printed. Labels are fed into the labelling mechanism from a label roll that has been loaded onto the machine.

2. Container feeding: Through a conveyor system or an automated container feeding mechanism, containers like bottles, jars, or cans are fed into the machine. In preparation for labelling, the containers move along the conveyor belt or are held in position by a container holder.

3. Labelling Mechanism: To apply adhesive labels to the containers, a number of interconnected parts form the labelling mechanism. Depending on the particular machine model, the precise design and operation may vary, but commonly includes the following:

- The labels are dispensed from the label roll and directed towards the labelling point during label dispensing. A labelling head may be used to separate and place the labels for application.

- Application of Glue: The machine uses glue or adhesive to coat the labels. Various tools, such as glue rollers, glue pads, or glue nozzles, can be used to do this. To guarantee appropriate adhesion, the glue is applied uniformly across the labels.

- Labelling Applicator: This person is in charge of carefully applying the labels to the containers. Depending on the needs of the application, it may employ strategies like wrap-around labelling, front and rear labelling, or top labelling.

4. Labelling Adjustment: Depending on the size and shape of the container, the machine may incorporate mechanisms to change the labelling position and orientation. This guarantees exact label positioning and alignment.

5. Container Handling: After the labels are placed on the containers, they are moved to the following step of the manufacturing process by conveyor or container handling equipment. Additional processing, packing, or inspection may be part of this.

6. Control system: The machine has a control system that monitors all aspects of the labelling procedure, including container handling, label application, glue application, labelling applicator movement, and labelling. Specific labelling parameters can be entered into the control system and changed as necessary.

Quality Control: To ensure label accuracy, label alignment, and label adherence, some fully automatic glue labelling machines may have quality control functions. In order to verify that the labelled containers match quality standards, this may utilise sensors or cameras.

A completely automatic glue labelling machine can operate and have different characteristics based on the machine model, the kind of containers being labelled, and the quantity of labels needed. Additional functions like real-time monitoring, data logging, configurable labelling parameters, and automatic label roll replacement may be included in more advanced devices.

To preserve the effectiveness and dependability of a fully automatic glue labelling machine as well as the precision and quality of the labelled containers, regular maintenance, cleaning of machine components, and adherence to safety regulations are essential.

Efficient Industrial Labeling

Our Fully Auto Glue Labeling Machine delivers consistent and swift application of labels for industrial products. The semi-automatic nature allows operators to maintain control while benefiting from automated glue dispensing, making it an excellent solution for medium to large-scale production needs.

Robust Build for Longevity

Constructed from premium mild steel, this machine ensures resilience and low maintenance over time. Its sturdy frame is designed to meet the rigorous demands of industrial usage, providing longevity and operational stability for your labeling processes.

FAQs of Fully Auto Glue Labeling Machine:

Q: How does the Human Machine Interface control system enhance the operation of this glue labeling machine?

A: The Human Machine Interface (HMI) simplifies user interaction, allowing operators to monitor and adjust settings easily through an intuitive digital interface, resulting in efficient and error-minimized labeling operations.Q: What type of labels can be applied using this machine?

A: This labeling machine is suitable for various self-adhesive and glue-based labels, making it adaptable for different product types in industrial settings, provided the label specifications match the machines capabilities.Q: When is it ideal to use a semi-automatic glue labeling machine for industrial applications?

A: A semi-automatic glue labeling machine is optimal when you need a balance between automation and operator intervention, typically for medium-volume production where flexibility and consistent quality are required.Q: Where is this labeling machine manufactured and can it be exported internationally?

A: The machine is manufactured in India and is available for export, making it accessible to industrial clients worldwide who require dependable labeling solutions for their production lines.Q: What is the process for setting up and operating this glue labeling machine?

A: To operate the machine, the operator uses the HMI to configure settings, prepares products and labels, and initiates labeling. The electric drive ensures smooth operation across production cycles, with glue dispensed and labels applied automatically.Q: How does using an electric drive benefit labeling efficiency?

A: An electric drive provides reliable, consistent power, resulting in smooth and accurate label application. This enhances productivity while reducing downtime associated with mechanical or manual labeling methods.Q: What are the main benefits of choosing this machine for industrial labeling needs?

A: Key benefits include robust mild steel construction, intuitive HMI controls, electric drive efficiency, ease of operation, and suitability for diverse industrial products, ensuring reliability and superior labeling quality.

More Products in Pet Bottle Labeling Machine Category

Fully Auto Heat Shrink Labeling Machine

Minimum Order Quantity : 1 Piece

Power Supply : Electric

Voltage : 220 Volt (v)

Drive Type : Electric

Material : Mild Steel

Control System : Human Machine Interface

|

|

|

|

ACCURAL BIOTECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry