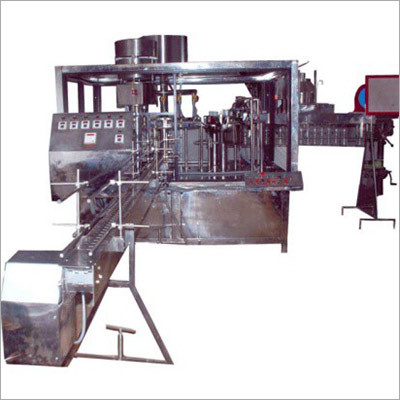

Semi-Auto Pet Bottle Packing Machine

Semi-Auto Pet Bottle Packing Machine Specification

- Usage

- Industrial

- Material

- Mild Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Voltage

- 220 Volt (v)

- Warranty

- 1 Year

Semi-Auto Pet Bottle Packing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Semi-Auto Pet Bottle Packing Machine

A specialised piece of equipment called a semi-automatic PET bottle packing machine is used to fill PET (polyethylene terephthalate) bottles or containers with different items including beverages, lubricants, detergents, or other liquid or semi-liquid substances. It is intended to automate the packaging procedure while still requiring some manual input to increase efficiency and accuracy.

The main parts and procedures of a typical semi-automatic PET bottle packing machine are summarised below:

1. Empty PET bottles are manually put onto the machine during bottle loading. The usual method of moving them through the packing process is to place them on a conveyor belt or place them into holders.

2. Product Supply: The device is linked to a system for supplying products, like a storage tank or a product filling device. To the packing machine, the product is pumped or transported and is prepared to be filled into PET bottles.

3. Filling Stations: Where the product is dispensed into the PET bottles is on the filling stations of the machine. Depending on the configuration of the machine and the required level of production, the number of filling stations may change.

- Filling Nozzles: The product is precisely dispensed into the bottles by one or more filling nozzles, one of which is present at each filling station. The quantity of nozzles is determined by the required output rate and the quantity of bottles being filled at once.

- Control system: The filling process is regulated by the machines control system, which guarantees exact volume control and filling operations. The desired fill volume for each bottle can be programmed.

4. After the bottles are filled, the device might have a mechanism for placing the lids. The bottles tops or lids are automatically applied by this process. The lids can be manually fed or fed from a lid magazine that has already been loaded.

5. After the bottles lids have been attached, the machine may include a station for capping or sealing. This area makes certain that the bottles lids are correctly fastened or sealed. Depending on the type of bottles and lids being used, the capping mechanism may be screw capping, snap-on lids, or induction sealing.

6. Labelling: An optional labelling capability may be available on some semi-automatic PET bottle packing machines. As a result, labels that provide product information, branding, or other necessary information can be applied to the bottles. Depending on the capabilities of the machine, the labelling procedure can be either human or automated.

7. Quality Control: To guarantee accurate filling volumes, lid placement, capping or sealing integrity, and label accuracy, quality control procedures can be included into the machine. Visual inspections, weight checks, or other testing techniques may be used in this to find and remove any flawed bottles from the production line.

8. Bottle Discharge: Following the packing procedure, the filled and sealed bottles are manually taken out of the machine and prepared for additional processing, labelling, or packaging.

Its crucial to remember that a semi-automatic PET bottle packing machine needs some manual assistance for operations like bottle loading, lid installation, and bottle removal. The filling and capping or sealing procedures are the main areas of automation, which helps to streamline the packaging process and increase productivity.

Depending on the machine model, the product being packed, the bottle size and shape, and the production needs, a semi-automatic PET bottle packaging machine may have different specialised features, functionalities, and modes of operation. To maintain the machines proper operation and the calibre of the packed PET bottles, regular maintenance, cleaning of machine components, and adherence to safety regulations are essential.

Efficient Semi-Automatic Packaging

This machine is tailored for industrial environments requiring speedy and consistent PET bottle packing. Its semi-automatic operation ensures a balance between manual intervention and automated processes, streamlining large-scale packaging with dependable results.

Durable Construction and Reliable Performance

Built from mild steel, the machine offers remarkable durability and longevity in demanding production conditions. Its electric drive and sturdy frame ensure reliable performance while minimizing maintenance needs and downtime.

User-Friendly Control System

Operators benefit from the intuitive Human Machine Interface, allowing easy adjustments and monitoring during packing tasks. The systems straightforward controls are designed to enhance productivity and reduce training time for staff in busy industrial settings.

FAQs of Semi-Auto Pet Bottle Packing Machine:

Q: How does the Semi-Auto Pet Bottle Packing Machine operate in an industrial setting?

A: This packing machine utilizes electric driving power and a Human Machine Interface for control. It requires some manual input to load and adjust PET bottles, while key packing steps are automated to achieve efficient and consistent bundling in industrial scenarios.Q: What materials are used in the construction of the machine, and how does this benefit users?

A: The machine is made from mild steel, offering robust structural integrity and resistance to wear. This ensures longevity and reduced maintenance, making it particularly suitable for extensive industrial usage.Q: When should I perform maintenance on the machine to ensure optimal operation?

A: Routine maintenance should be conducted as recommended by the manufacturer, ideally after every production cycle or as per your operational intensity. Always check for wear, clean moving components, and inspect the electric drive regularly to sustain peak efficiency.Q: Where is this Semi-Auto Pet Bottle Packing Machine primarily used or exported?

A: This machine is chiefly utilized in industrial sectors within India, but it is also exported by manufacturers and suppliers to various markets requiring efficient bottle packaging solutions.Q: What is the process for packing bottles using this machine?

A: Operators need to load the PET bottles onto the packing tray, adjust the Human Machine Interface for required settings, and initiate the packing sequence. The machine then systematically bundles and secures the bottles, readying them for shipment or storage.Q: How does using this machine benefit my packing operations compared to manual methods?

A: Using the Semi-Auto Pet Bottle Packing Machine increases productivity, reduces labor effort, and improves uniformity in packing. The machines semi-automatic features provide a substantial boost in speed and reliability over manual packing procedures.

More Products in Pet Bottle Packing Machine Category

Fully Auto Pet Bottle Packing Machine

Minimum Order Quantity : 1 Set

Material : Liquid

Automatic Grade : Automatic

Auxiliary Packaging Machine Type : Other

Computerized : No

Warranty : 1 Year

|

|

|

|

ACCURAL BIOTECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry