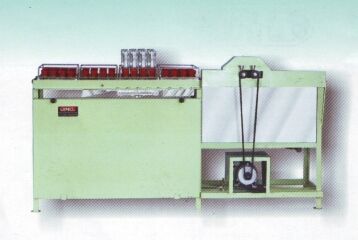

Glass Bottle Washing Unit

Glass Bottle Washing Unit Specification

- Warranty

- 1 Year

- Usage & Applications

- Industrial

- Frequency

- 50 Hertz (HZ)

- Drive Type

- Electric

- Water Source

- River Water

- Automatic Grade

- Semi Automatic

- Material

- Mild Steel

Glass Bottle Washing Unit Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Glass Bottle Washing Unit

The purpose of a glass bottle washing unit, sometimes referred to as a bottle washer or bottle cleaning machine, is to clean and sanitise glass bottles before they are filled with liquids or other products. The device is frequently used in sectors where upholding cleanliness and hygiene is essential, including beverage production, breweries, vineyards, and medicines.

The main elements and procedures in a typical glass bottle washing unit are summarised below:

1. Bottle loading and unloading: Bottles can be loaded manually or automatically onto the machine. Empty bottles are often inserted into bottle holders or carriers that move through the cleaning process, or they are placed on a conveyor belt. The bottles are removed from the machine after cleaning.

2. Pre-Rinsing: During this preliminary step, bottles are rinsed in water to get rid of any loose particles, dust, or residue that may have accumulated on their surfaces. Depending on the cleaning requirements, the pre-rinse may be carried out using warm water or water that is at room temperature.

3. Main Cleaning Stage: To properly eliminate impurities, the bottles go through a number of cleaning processes. Usually, a combination of mechanical operations, high-pressure water jets, and detergent solutions are used throughout these stages. Depending on the particular equipment and cleaning requirements, the precise design and number of cleaning stages may change.

- Spinning Brushes: To clean the inside and outside of the bottles of debris, labels, and other remnants, spinning brushes or spray heads with rotating nozzles are used.

- High-Pressure Water Jets: To remove any last bits of debris and pollutants, strong water jets are pointed in different directions at the bottles.

- Detergent Injection: To help remove tough stains, organic material, or microbial pollutants, detergent solutions or sanitising agents may be injected into the cleaning process.

4. Intermediate Rinses: Following the primary cleaning cycle, the bottles go through intermediate rinses to get rid of detergent residues and any lingering pollutants. To guarantee thorough cleaning, multiple rinse steps may be used.

5. last Sanitization: To get rid of any potential pathogens or microbiological contamination, bottles are given a last sanitising treatment at this stage. Various techniques, including hot water rinses, steam sterilisation, or chemical sanitization utilising disinfectants or sanitising solutions, can be used to achieve this.

6. Drying: Depending on the machine model, hot air blowers, hoover systems or other drying techniques may be used to dry bottles. To avoid water stains, bacterial growth, or product contamination, drying must be done correctly.

7. Checking for cleanliness, lingering particles, or faults is done using inspection and quality control systems in some bottle washing equipment. This guarantees that only bottles that have been thoroughly cleaned move on to the filling or packing stage.

Depending on the exact machine model and the needs of the sector, a glass bottle washing units characteristics and operation can change. Additional features like automatic loading and unloading, programmable cleaning cycles, changeable cleaning parameters, and integrated monitoring systems may be included in more complex units.

In order to ensure the efficient and successful operation of a glass bottle washing unit and to preserve the cleanliness and calibre of the bottles used in production processes, proper maintenance, regular cleaning of the machine components, and attention to hygiene and safety rules are needed.

Efficient Industrial Bottle Cleaning

The Glass Bottle Washing Unit is ideal for industrial setups demanding consistent hygiene and rapid turnaround. Built with mild steel, it withstands rigorous use while delivering reliable cleaning with its semi-automatic operation. This unit caters perfectly to bottling plants and beverage industries seeking a balance of automation and manual control.

Reliable Performance with Electric Drive

Operating at 50 Hertz, the electric drive provides steady power, ensuring that your bottle cleaning process runs smoothly and without interruption. The systems semi-automatic grade allows operators to monitor performance while minimizing hands-on maintenance.

FAQs of Glass Bottle Washing Unit:

Q: How does the Glass Bottle Washing Unit operate?

A: The washing unit works with an electric drive at 50 Hertz, utilizing river water as the cleaning source. It automates major washing processes while requiring limited manual supervision, making it efficient and easy to operate in industrial environments.Q: What materials are used in the construction of the washing unit?

A: The unit is constructed from high-quality mild steel, which offers both durability and resistance to corrosion, ensuring a long operational life even in demanding industrial conditions.Q: When is routine maintenance recommended for optimal performance?

A: Routine maintenance should be performed at regular intervals as guided in the product manual, typically after every significant production cycle. This ensures that the system runs efficiently and the 1-year warranty remains valid.Q: Where can the unit be installed for best results?

A: The Glass Bottle Washing Unit is best installed in dedicated industrial bottling or rinsing sections with access to river water and appropriate electric supply, as outlined in the installation guide.Q: What is the cleaning process for glass bottles in this unit?

A: The process involves loading glass bottles onto the unit, where they are automatically washed using river water and then rinsed as per preset cycles. Operators monitor the system, intervening only when necessary.Q: What are the main benefits of using this washing unit?

A: Key benefits include reduced labor costs due to semi-automation, consistent and thorough cleaning, reliable durability thanks to mild steel construction, and the assurance of a 1-year warranty. Its suitability for various bottle sizes adds flexibility for diverse industrial needs.

More Products in Soda Soft Drink Plant Category

Carbonator Tank with Pump and Motor Assembly

Minimum Order Quantity : 1 Piece

Frequency : 50 Hertz (HZ)

Material : Mild Steel

Warranty : 1 Year

Voltage : 220440 Volt (v)

Usage & Applications : Industrial

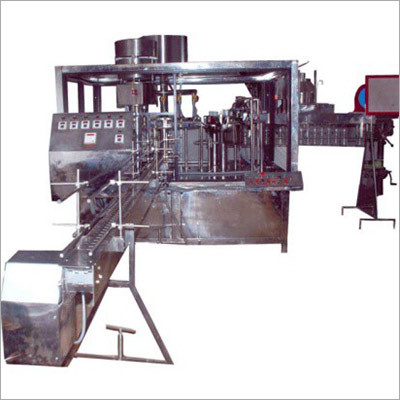

Aeriated Water Filler and Cork Sealer

Minimum Order Quantity : 1 Piece

Frequency : 50 Hertz (HZ)

Material : Mild Steel

Warranty : 1 Year

Voltage : 220440 Volt (v)

Usage & Applications : Industrial

|

|

|

|

ACCURAL BIOTECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry