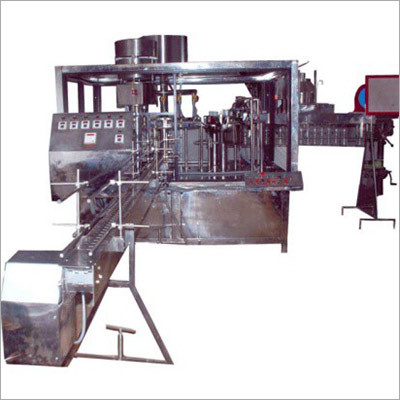

Jar Washing Machine

Jar Washing Machine Specification

- Power Supply

- Electric

- Usage

- Industrial

- Material

- Mild Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Voltage

- 220 Volt (v)

- Color

- Silver

- Warranty

- 1 Year

Jar Washing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Jar Washing Machine

A jar washing machine, often referred to as a jar washer or jar cleaning machine, is a specific piece of machinery used to clean and sanitise jars or containers in a variety of industries, including food processing, pharmaceuticals, cosmetics, and more. The equipment is made to remove pollutants from the jars, making sure they are fully cleaned and prepared for filling or packaging.

The main parts and procedures in a typical jar washing machine are summarised below:

1. Jar loading and unloading: Empty jars can be loaded manually or automatically onto the machine. Usually, the jars are put into holders that go through the cleaning process on a conveyor belt. The cleaned jars are removed from the machine after cleaning.

2. Pre-Rinsing: To remove any loose debris, dust, or residue from the surfaces of the jars, they are first given a pre-rinse with water or a cleaning solution. Prior to the primary cleaning procedure, this step aids in loosening and removing bigger particles.

3. The jars go through the main cleaning stage, where they are put through a number of cleaning procedures to completely remove impurities. Depending on the particular equipment and cleaning requirements, the precise design and number of cleaning stages may change.

- High-pressure water jets are used to effectively dislodge and remove tenacious debris, residues, or particles from the jars. These strong water jets or nozzles are used to spray high-pressure water onto the jars.

- Brushes or Scrubbers: To further loosen and remove dirt or residues, rotating brushes or scrubbers may be used to mechanically scrape the surfaces of the jars.

- Cleaning Agents or Detergents: Cleaning agents or detergents may be used to the cleaning procedure to improve the removal of oily or sticky residues. To make cleaning easier, the detergent is generally sprayed or circulated throughout the jars.

4. Intermediate Rinses: Following the primary cleaning cycle, the jars undergo intermediate rinses to get rid of any last bits of cleaning agent or detergent. To guarantee thorough cleaning, multiple rinse steps may be used.

5. Final Sanitization: At this stage, the jars go through a final sanitization procedure to get rid of any microbiological contamination or potential pathogens. This can be accomplished using a variety of techniques, including steam sterilisation, hot water rinses, or chemical sanitization utilising disinfectants or sanitising solutions.

6. Drying: The jars may go through a drying process to get rid of extra water or moisture, depending on the design of the particular machine. Hot air blowers, hoover systems or other drying processes can be used to accomplish this.

7. Inspection and quality control: Some jar washers include inspection systems built in to look for dirt, leftover particles, or flaws. As a result, only jars that have been thoroughly cleaned can move on to the filling or packaging stage.

Depending on the particular machine model, the demands of the sector, and the kinds of jars or containers being cleaned, jar washing machines can operate and have different functions. Advanced machines may include features like programmable cleaning cycles, automatic loading and unloading, integrated monitoring systems, and cleaning parameters that may be adjusted.

To ensure the efficient and effective operation of a jar washing machine and to maintain the cleanliness and quality of the jars used in manufacturing processes, proper maintenance, regular cleaning of machine components, and adherence to hygiene and safety rules are important.

Efficient Industrial Solution

Our Jar Washing Machine streamlines the cleaning process for large-scale facilities, combining semi-automatic controls and durable mild steel material. With a silver finish and a 220-volt electric supply, it ensures robust performance while remaining energy efficient. This machine is ideal for manufacturers or suppliers needing consistent, reliable operation for jar cleaning.

Built to Last

Designed with industrial-grade mild steel, this washing machine is built to withstand rigorous daily use. The 1-year warranty underscores our commitment to product longevity and customer satisfaction, while the non-computerized design allows for straightforward maintenance and ease of use in busy environments.

FAQs of Jar Washing Machine:

Q: How does the Jar Washing Machine operate for industrial usage?

A: The machine runs on electric power at 220 volts and utilizes a semi-automatic system, allowing operators to clean jars efficiently with minimal manual effort, optimizing workflow in industrial settings.Q: What materials are used in constructing the Jar Washing Machine?

A: This machine is crafted from high-quality mild steel, ensuring durability, resistance to corrosion, and suitability for demanding industrial environments.Q: When should routine maintenance be performed on the Jar Washing Machine?

A: We recommend conducting routine maintenance every few months or as specified in the user manual to ensure longevity and optimal performance. Regular cleaning and inspection help prevent any potential issues.Q: Where can this washing machine be purchased or exported from?

A: As an exporter, manufacturer, and supplier, we provide the Jar Washing Machine directly from India. Interested buyers can contact us for purchases, exports, or bulk supply inquiries.Q: What is the process involved in operating this semi-automatic machine?

A: Operators load jars into the machine, select the appropriate washing setting, and supervise the cleaning cycle. The semi-automatic design requires minimal manual intervention but does not need specialized computer controls.Q: What are the major benefits of choosing this jar washing machine?

A: Its semi-automatic operation boosts productivity while the mild steel construction offers longevity. The 1-year warranty further assures peace of mind. Its suitable for high-volume industrial use and helps streamline your cleaning process.

More Products in Jar Washing Machine Category

Fully Automatic Jar Filling Machine

Minimum Order Quantity : 1 Piece

Power : 3 Phase Watt (w)

Weight (kg) : 150 Kilograms (kg)

Computerized : Yes

Material : Liquid

Automatic Grade : Automatic

|

|

|

|

ACCURAL BIOTECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry